FuzEvent for Waste-to-Energy Plants

FuzEvent is the high-level control tool for waste-to-energy and Biomass plants.

The FuzEvent® System is the ultimate operator assistant. The starting point for the design is to apply the same behavior as the best operators and thereby achieve unique results when it reacts correctly 24/7. Implementation of FuzEvent® is always done in close collaboration with the operators from whom extremely important plant operational expertise is integrated into the control.

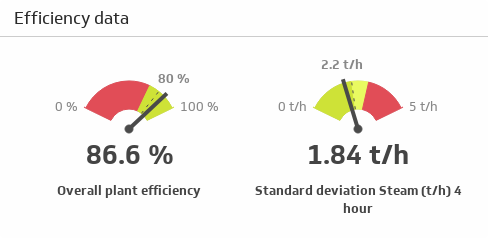

The FuzEvent® is able to provide substantial improvement in the combustion stability, more stable operation can directly be reflected into increased plant performance generating more than 5% higher steam production, 20% less flue gas temperature variations, 20 % improved efficiency of the flue gas treatment system, and 5% increased overall longterm plant efficiency

Correct process control actions in due time creates stability.

Plant operates closer to set-points, less needs for safety margins.

Optimized stability creates less fouling less thermal wear increasing availability.

Handle the process also during critical process conditions.

Open control strategy. no black box hiding the control strategy.

Applying special strategies to special challenging process conditions.

A FuzEvent based operator support system has a strong impact on the daily work done by the operators. It is therefore very important to keep the operators updated about the functions and to build in new ideas created by the operators or suggested by Dublix. The Dublix Service Concept includes:

Discuss the updated performance report from the recent period.

Check of the practical experience from the use of remote applied optimization service.

Evaluate and adjust the KPI dashboard functions to reflect the current needs from the plant.

Agree and implement suggested optimization improvement from operators and Dublix.

Check of the installed computer equipment and evaluate the needs for upgrade or exchange of HW/SW.

Carry out training of staff in the optimization system

FuzEvent is the high-level control tool for waste-to-energy and Biomass plants.

2*5 Ton/h WtE Plant operating FuzEvent on a Seghers Combustion grate system since 2011

The result of the implemented system in 2011 was impressive. We have obtained 10% more electricity production and the waste treatment capacity has increased by 6.5% registered each year during the first two years of operation.

The annual waste treatment capacity was increased with total 4.000 ton/year.

2*10 Ton/h WtE Plant operating FuzEvent High Level Control on Martin Combustion grate system since 2011. After more than 3 years of operation our conclusions are:

The FuzEvent handles the complete combustion control with very high efficiency. FuzEvent is fully accepted by the operators and is controlling more than 95% of the time

The plant is able to handle very high CV values (2800-2900 Kcal/kg)

The Advanced IR camera provides important useful information for the FuzEvent combustions control and the operators

Let us contact you to discuss how we can help your plant.

Why do we need a high level automatic combustion control?

At most WTE plants only a few very experienced operators can handle the complexities of constantly obtaining optimal operation efficiency and consider this a very demanding and troublesome task. Therefore, a high-level control system that operates the combustion system of the plant in the same way as the most experienced operator is a very attractive tool to do the work to the same standards 24 hours/day.

Why choose FuzEvent?

Dublix, with its FuzEvent High-Level control system, offers a feature to interact and operate in the process in due time and in particular when the process behaviour has shown maximum information about its previous behaviour, just like an experienced operator.

How is the FuzEvent system specified to your plant?

The typical operator interactions are described during the design meeting, and will vary from plant to plant; the main aims are to keep the operators in charge of the operation, and to use their knowledge to make their work much more efficient by reducing routine operator interactions.

What are the achievements?

Typically, a Dublix FuzEvent system obtains 95% to 98% fully automatic control of all connected set-points. As a result, an overall increased efficiency of the plant is established with:

What if some changes need to be made after the installation of the FuzEvent?

Compared to most automatic combustion control systems, FuzEvent is easily modified to cope with the changing environment and to adapt new ideas for more efficient operation at the plant. The system does not contain a black box philosophy nor does it hide its functions. Furthermore, Dublix offers a Service Contract to provide you with assistance to carry out continuous optimization and updates on the software.

What if some new staff is recruited that does not know how to operate FuzEvent?

Dublix also offers in its Service Contract regular training sessions by specialists for any new staff at the plant.

Is it necessary to modify the existing control system on the plant when a FuzEvent system is installed?

No modification is needed in the existing control system. Exchanges of process data and set points adjustments are done through a standard communication protocol. A watch dog function is implemented in order to keep track of a well-functioning data exchange.

Will the existent control system work if the FuzEvent system is switched off?

The FuzEvent system can always be switched off by the operators for example during test of new functions or in special situations. In case of communication problem (between FuzEvent and the existing control system), the FuzEvent system will automatically be switched off. After the switch off of FuzEvent, the plant will then operate as before the FuzEvent system was implemented, e.g. based on the existing control system functions.